The Process

All Paintings are on 100% silk, several different types, as noted. I begin with white silk, by the yard, or scarves already sized and hand hemmed with silk thread (something I could not even begin to do). I wash them by hand to prepare them to be stretched upon a wooden frame and when dry are ready to paint. My designs are all original drawings I create.

Using my light table, I am then able to transfer them to the silk. I am now using an "aqua gutta" resist. this allows control of the distribution of the dyes, fencing in areas of one color from another. I paint in a watercolor style with brushes. I often repeat this sequence several times till I get desired effects – depth of colors and infinite variations of them.

When painting is completed, the silk is removed from stretcher and rolled between sheets of non printed newspaper into a tube. At this point the steamer is being prepared. Handmade with a double-walled vent pipe and insulated, the steamer is now set over boiling water on a hot plate. The tube with paintings rolled inside is hung inside this pipe and then topped with lots of newspapers and towel to absorb any dripping steam and to contain steam within pipe. This nerve wracking step lasts from 1 1/2 hours to 3+ hours. Next they are removed and allowed to "set" for 24 hours. They are now washed, with Synthropol, then fabric conditioned to bring back the natural hand of the silk – YUM!

And last they are ironed on delicate setting, misted as needed to get a perfect product ready for you!

Using my light table, I am then able to transfer them to the silk. I am now using an "aqua gutta" resist. this allows control of the distribution of the dyes, fencing in areas of one color from another. I paint in a watercolor style with brushes. I often repeat this sequence several times till I get desired effects – depth of colors and infinite variations of them.

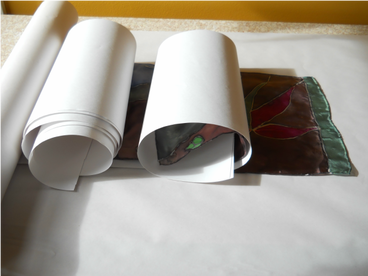

When painting is completed, the silk is removed from stretcher and rolled between sheets of non printed newspaper into a tube. At this point the steamer is being prepared. Handmade with a double-walled vent pipe and insulated, the steamer is now set over boiling water on a hot plate. The tube with paintings rolled inside is hung inside this pipe and then topped with lots of newspapers and towel to absorb any dripping steam and to contain steam within pipe. This nerve wracking step lasts from 1 1/2 hours to 3+ hours. Next they are removed and allowed to "set" for 24 hours. They are now washed, with Synthropol, then fabric conditioned to bring back the natural hand of the silk – YUM!

And last they are ironed on delicate setting, misted as needed to get a perfect product ready for you!

The Stretcher

|

Here is Margie, one of my students, working on her painting The silk is clipped to a wooden frame designed by my brother, Paul. The frame design allows me to change size of frame to fit any size scarf or fabric ~ he's a genius.

The fabric is suspended using clips attached to frame with elastics. Here the aqua gutta is being applied with a squeeze bottle. This piece was accomplished in several stages, with several applications of gutta and then painting, then gutta again. She just couldn't keep it simple. This was a scarf Margie inherited from her Mom last year, and she chose to create a design in her honor. What a beautiful piece! |

The Steamer

Here is the steamer that allows me to set the dyes. In this process the dye painted onto the silk, actually becomes part of the fabric thru chemical interaction. The steam heat is the secret! Amazing!